ANSYS-CFX Pump Simulation

Important notes

1- All tutorial geometries are available: You can contact me by email: almakky@hotmail.co.uk and the mesh will be sent to your email account.

2- Please don’t send me an email asking me to send you tutorials, what is available has been uploaded on the website.

3- I would very much appreciate any feedback about the tutorials, and your contribution will be stated in the tutorial, I plan to update the tutorials.

1- All tutorial geometries are available: You can contact me by email: almakky@hotmail.co.uk and the mesh will be sent to your email account.

2- Please don’t send me an email asking me to send you tutorials, what is available has been uploaded on the website.

3- I would very much appreciate any feedback about the tutorials, and your contribution will be stated in the tutorial, I plan to update the tutorials.

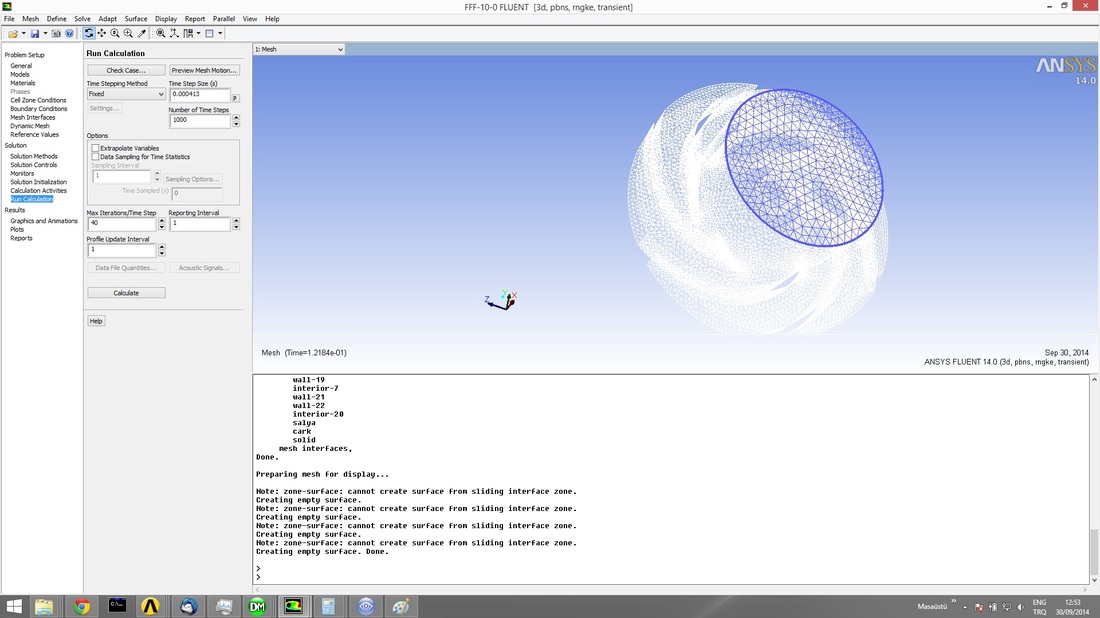

Time Stepping for Turbomachinary

When studying turbomachinary the occurring speeds are high. You will need to know what is the required time for a full rotaion of the turbine rotor. Then based on that you can think of how much detail you want to capture during one full rotation. Some times three time steps are required, it all depends on that can you curve fit the generated data with the experimental data. Then comes how much generated data for each saved time step and is it necessary for that detail.

Duration_of_One_Full_Rotation = This is Calculated by Researcher.

Number_of_Time_Steps = This is estimated by how much storage capacity is available and what type of experimental data is available.

Time_Step = This is the unknown value.

Number_of_Rotations = This is estimated by how much storage capacity is available and what time of experimental data is available, you can take its value as 1 initially.

Duration_of_Simulation=Number_of_Time_Steps*Time_Step*Number_of_Rotations*Duration_of_One_Full_Rotation

Duration_of_One_Full_Rotation = This is Calculated by Researcher.

Number_of_Time_Steps = This is estimated by how much storage capacity is available and what type of experimental data is available.

Time_Step = This is the unknown value.

Number_of_Rotations = This is estimated by how much storage capacity is available and what time of experimental data is available, you can take its value as 1 initially.

Duration_of_Simulation=Number_of_Time_Steps*Time_Step*Number_of_Rotations*Duration_of_One_Full_Rotation

Applying the Cavitation Option

Under Construction.

Introductory Material

My dear friend Mr ROGER IVAN PONCE SEGOVIA has been of great in giving his valuable input for this introduction section of the tutorial:

There are two ways to simulate turbomachinery:

1- At steady state (it is easier and saves time simulation).

2- In transient state.

If you want to do steady state you must select the stationary zone and activate "Wall Velocity"> Counter rotating Wall. Besides'd need only draw a quarter of your geometry.

Modify your geometry with this indication; and see if the error continues.

Important Note: Also check that the axis of the rotor and stator are located in the same place.

Also I commented that the interface options "frozen rotor" are for steady state and the "stator rotor transient" are for transient.

It is also possible to activate cavitation if necessary for analysis.

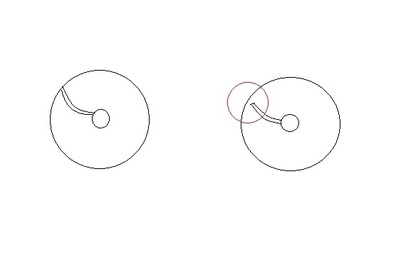

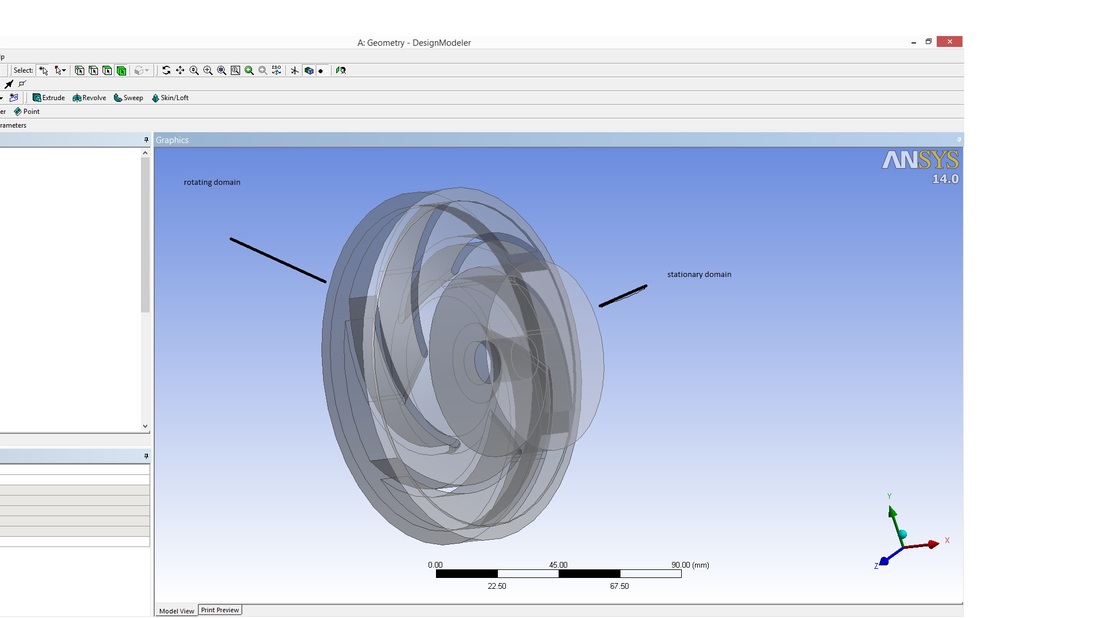

If you want to simulate transient I suggest you add a little space between the blade and the casing of the pump (see figure below).

There are two ways to simulate turbomachinery:

1- At steady state (it is easier and saves time simulation).

2- In transient state.

If you want to do steady state you must select the stationary zone and activate "Wall Velocity"> Counter rotating Wall. Besides'd need only draw a quarter of your geometry.

Modify your geometry with this indication; and see if the error continues.

Important Note: Also check that the axis of the rotor and stator are located in the same place.

Also I commented that the interface options "frozen rotor" are for steady state and the "stator rotor transient" are for transient.

It is also possible to activate cavitation if necessary for analysis.

If you want to simulate transient I suggest you add a little space between the blade and the casing of the pump (see figure below).

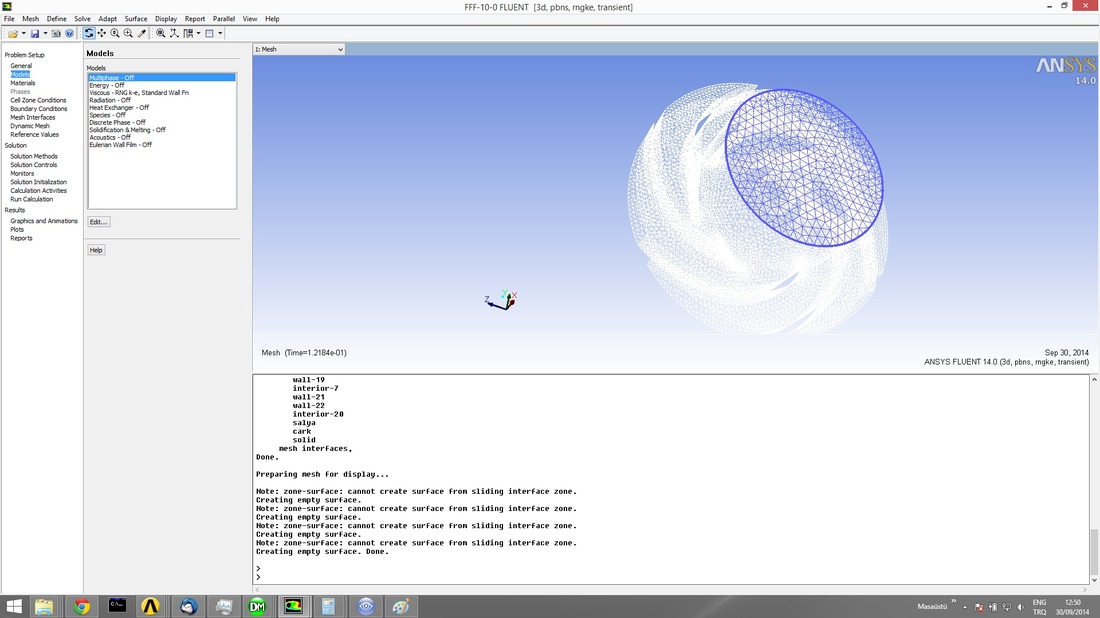

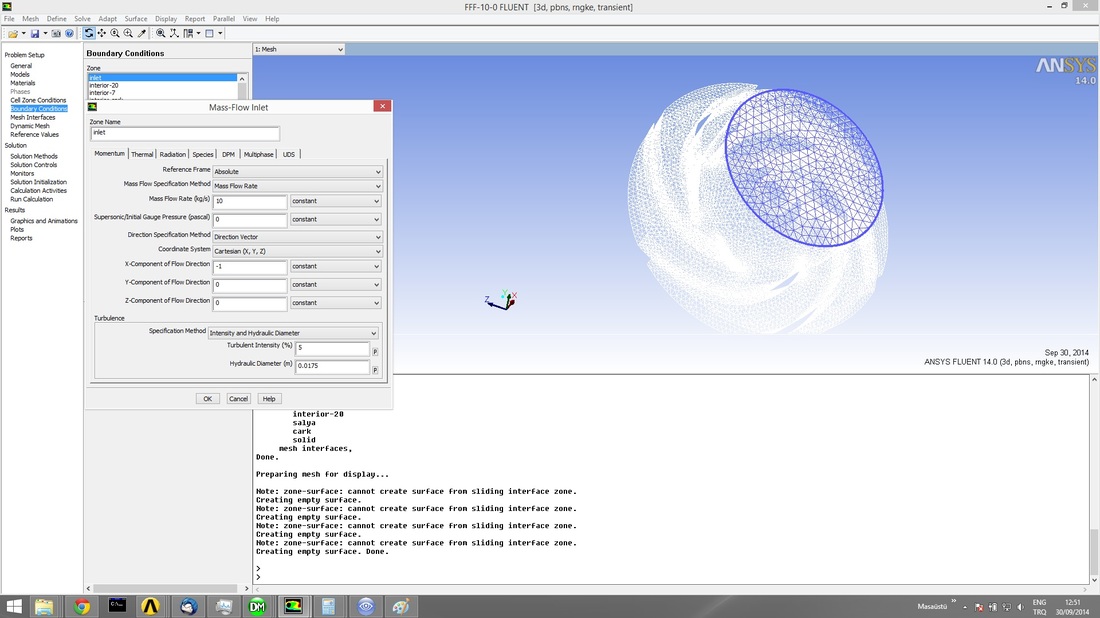

Simulation Setup

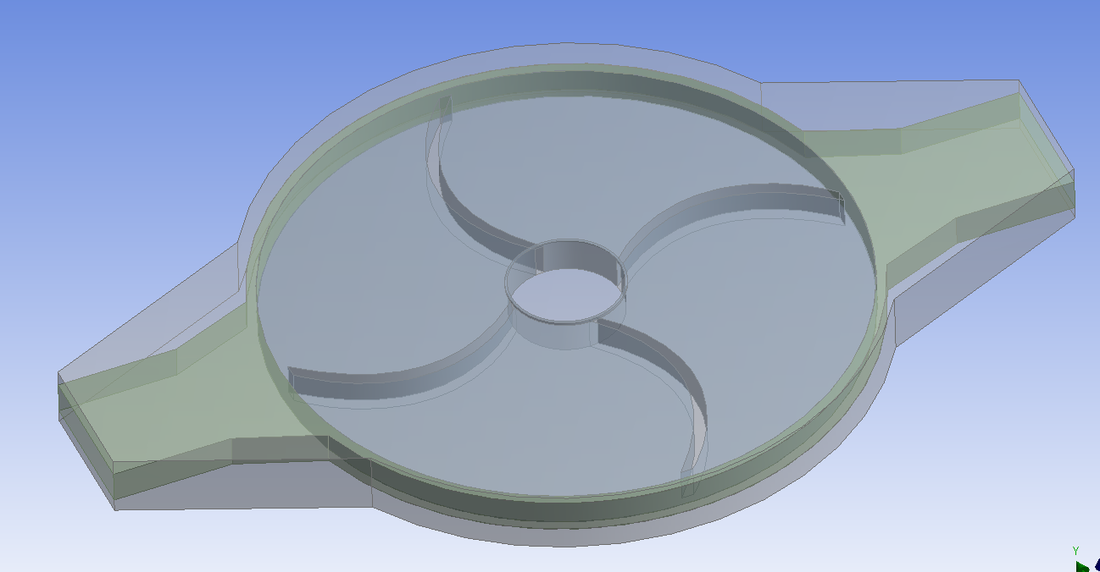

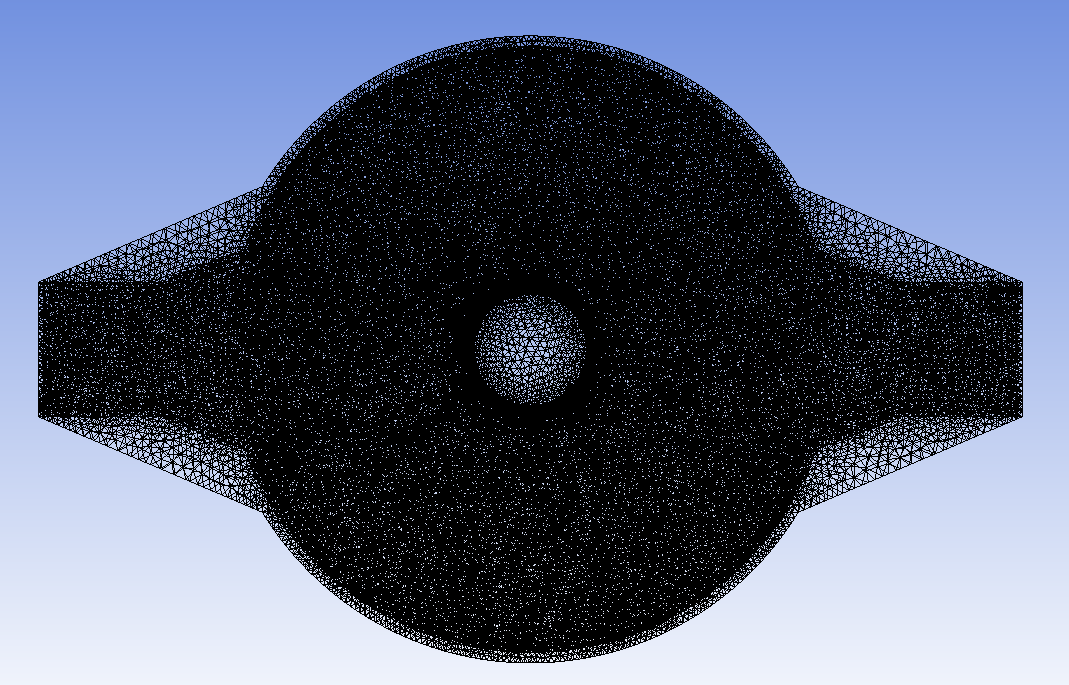

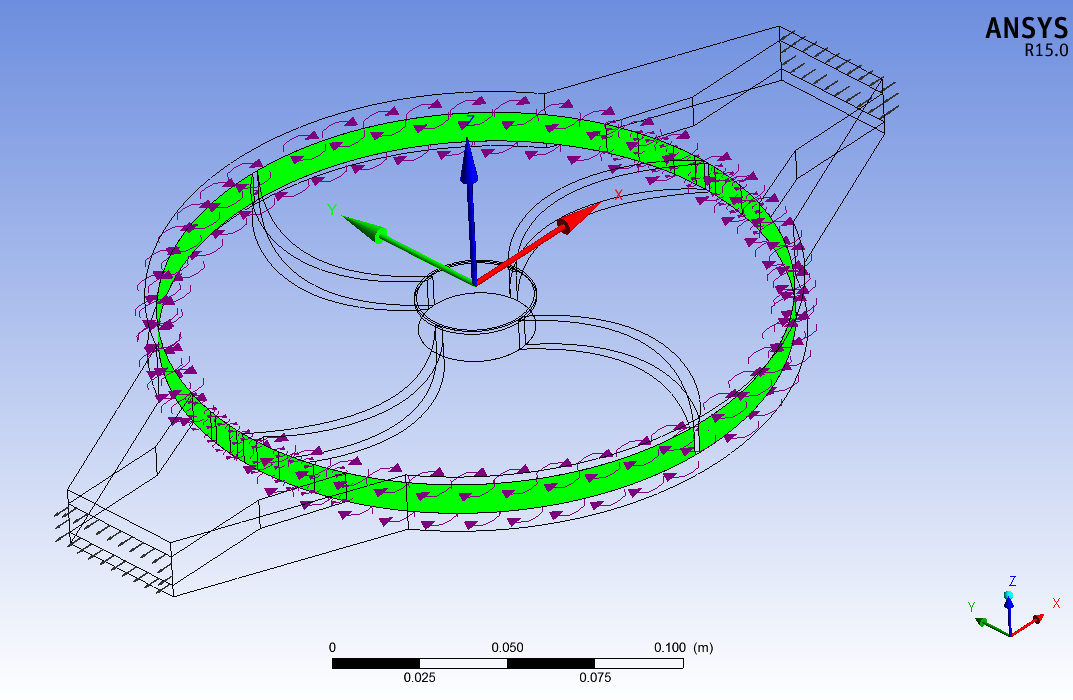

Step 1: You will require four geometries

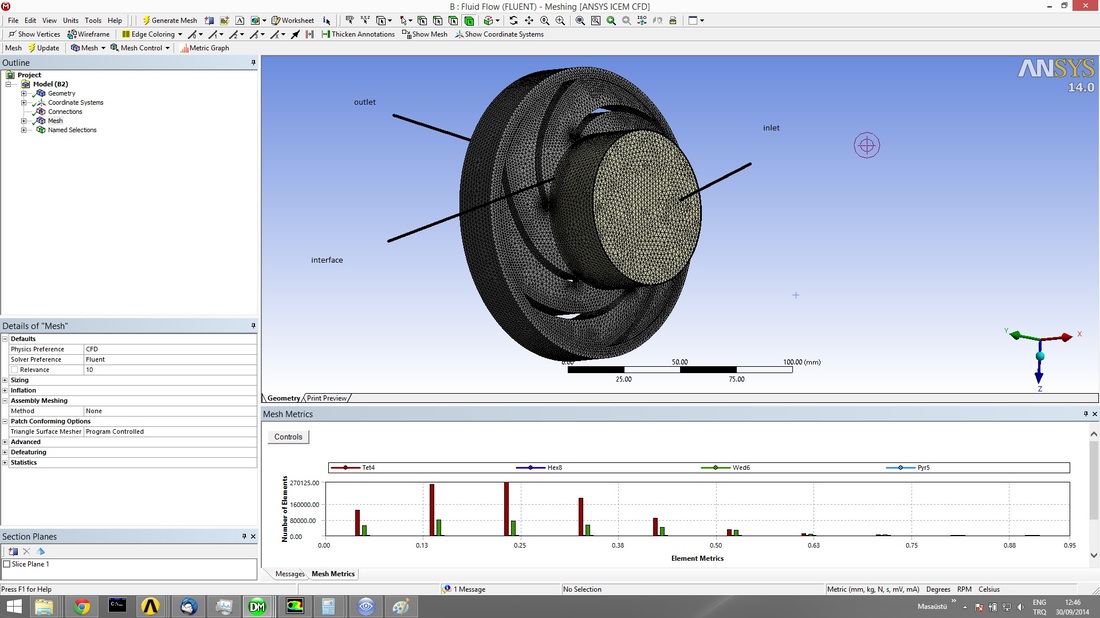

Step 2: You will need to generated a mesh for each geometry.

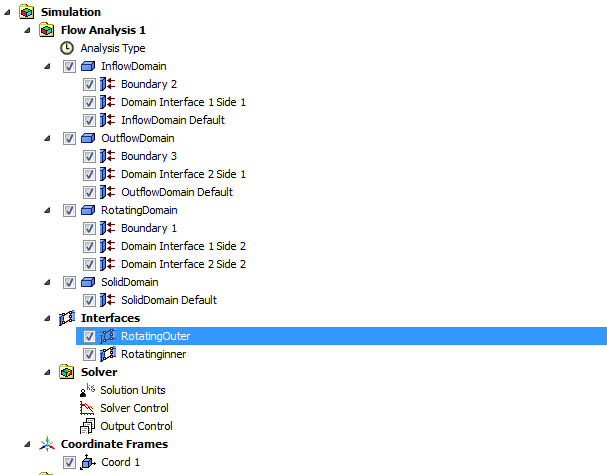

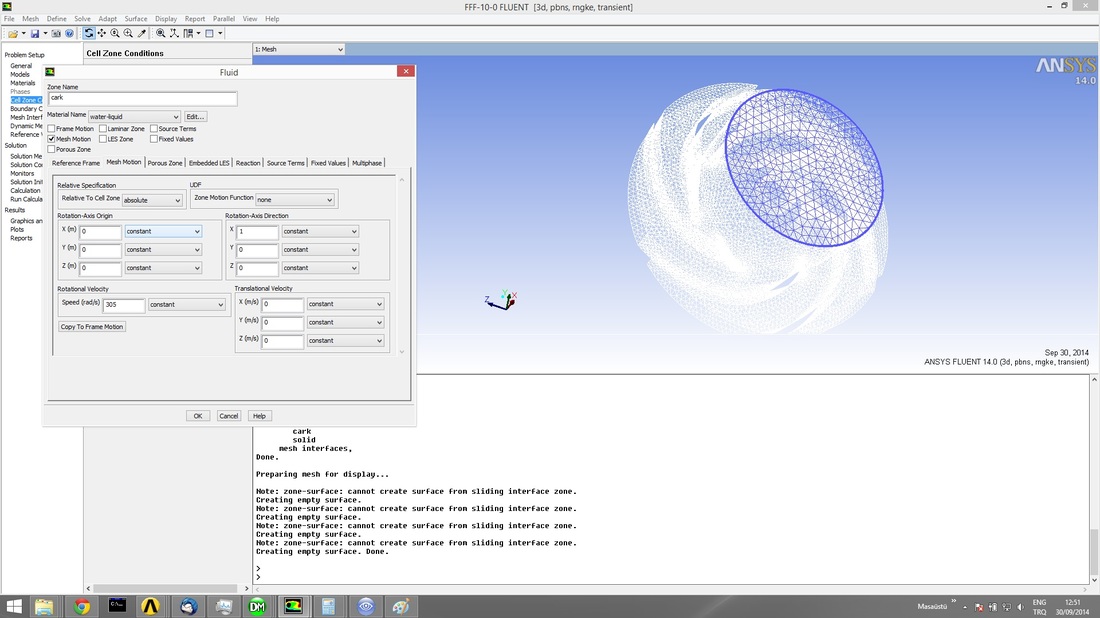

Step 3: You will need 4 domains in addition to the interface region definitions.

Step 4: You will also require an axis of rotation for the impeller domain

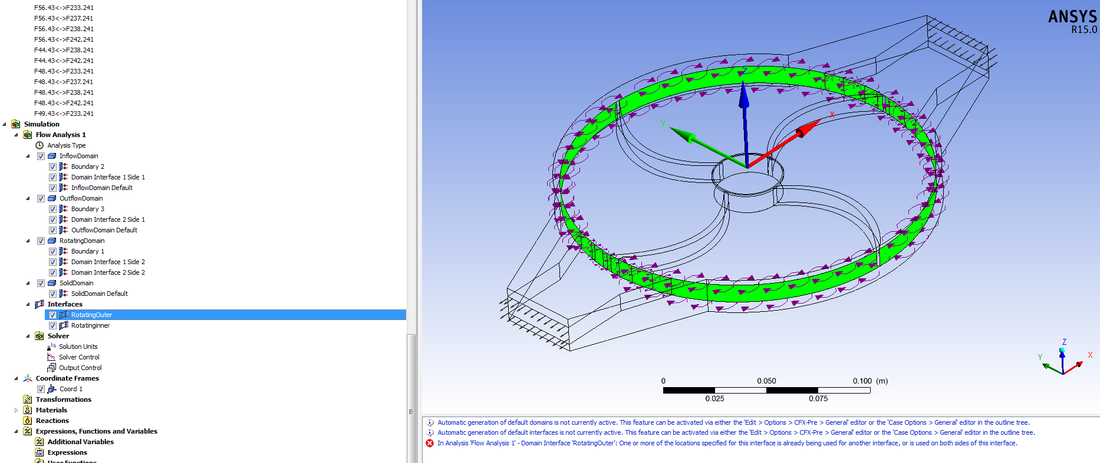

Step 5: I have checked and defined the interfaces but cannot proceed.

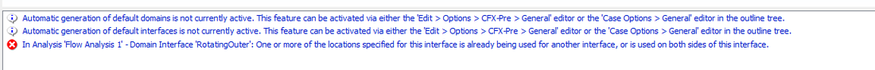

Step 6: I got this error and stopped

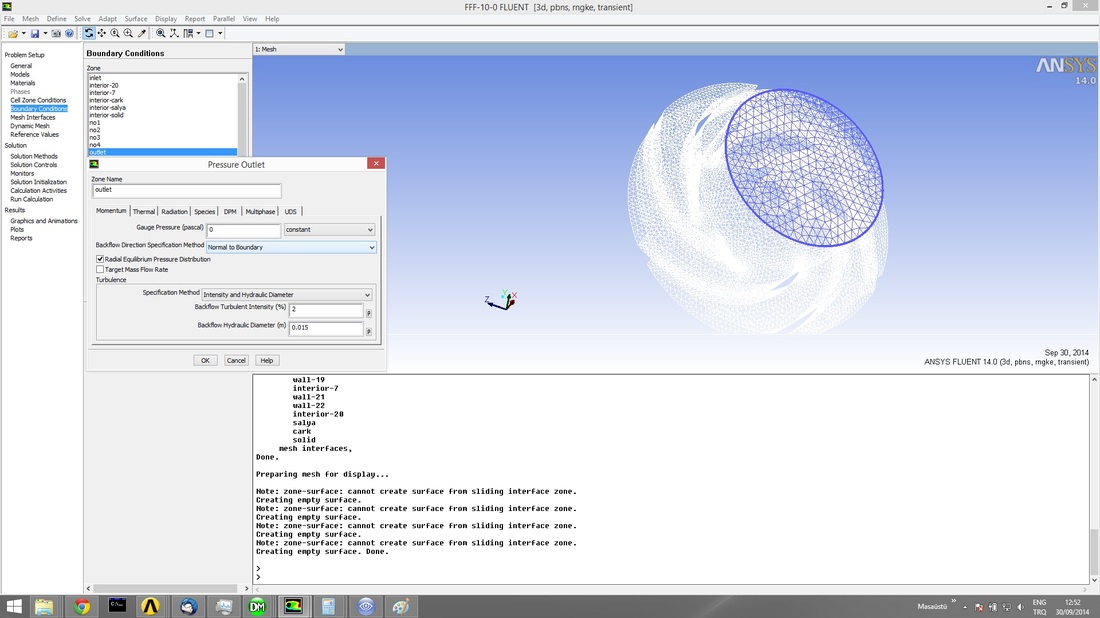

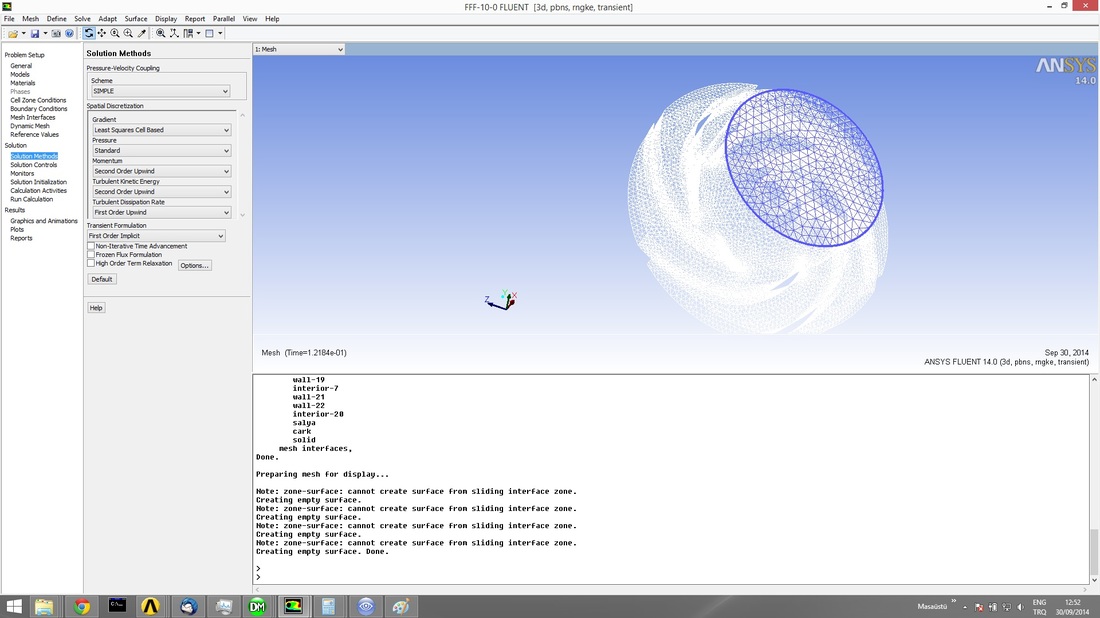

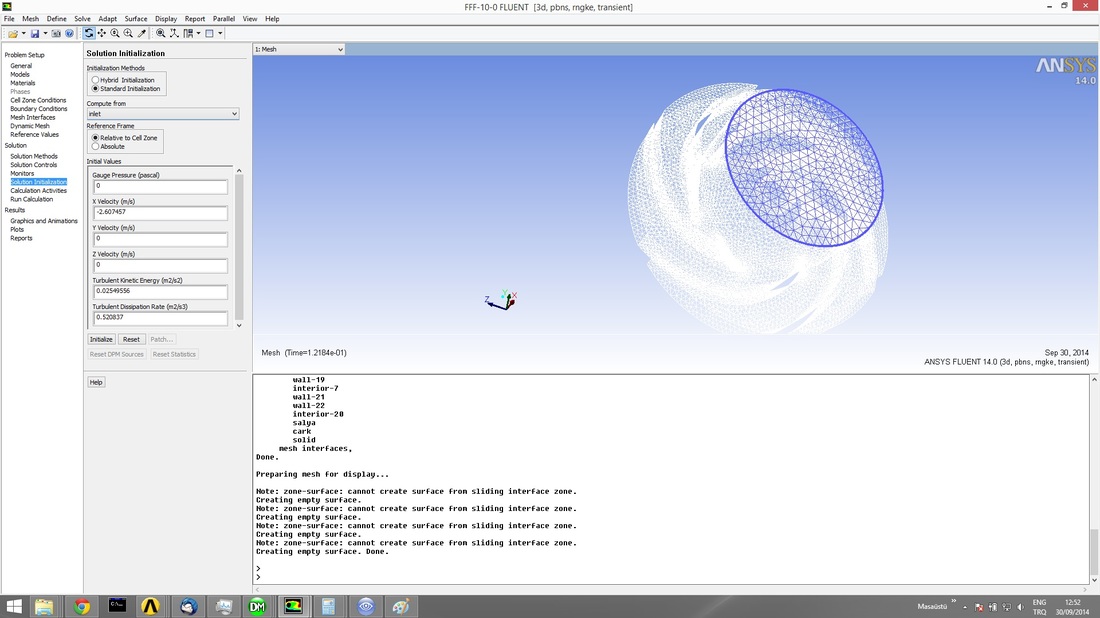

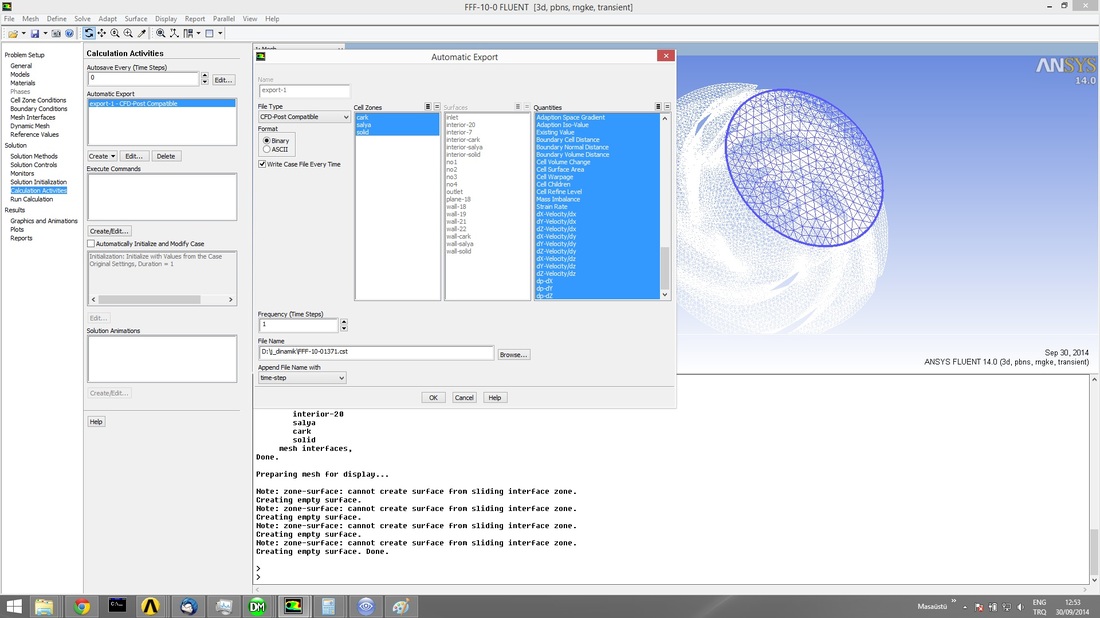

ANSYS FLUENT Pump Simulation

Unless otherwise noted, all content on this site is @Copyright by Ahmed Al Makky 2012-2014 - http://cfd2012.com