Number of Iterations

Building numerical simulations needs the researcher to know what he is doing, researchers have developed tools for code users to check that what they are doing is correct or not. The more you work with numerical codes the more you become experienced and confident in what you are doing. This results in that the scientist develops steps to speed up his work and also to check it is correct.

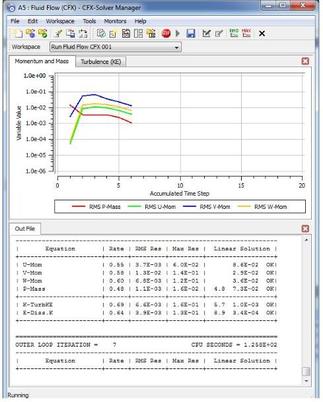

One of the first indicators that your simulation calculation is progressing on the right path is through monitoring the convergence of the iteration this can be seen the following image below

The different color plots shows the convergence rate of each solved equation, all these tools help the user to quickly identify

Convergence of simulation is achieved after a number of time steps.

The next questions that comes to mind, what is an iteration, Iteration means the act of repeating a process with the aim of approaching a desired goal, target or result, so that leads us to asking what is the desired goal? that is specified by the researcher on how many zeros he wants to see after a dot meaning 0.00000....., that would require a reasonable amount of allocated software depending on the wanted accuracy.

This tells us for the required goal needs their has to be some kind of stopping criteria, CFD software are provided a stopping criteria that is either through a default condition of stopping the calculation after a number of iterations or by the user specifying the stopping criteria at a certain condition.

Steady State Time Scale Control

For steady-state problems, the CFX-Solver applies a false timestep as a means of under-relaxing the equations as they iterate towards the final solution. Because the solver formulation is robust and fully implicit, a relatively large time scale can typically be selected, so that the convergence to steady-state is as fast as possible.

A steady-state calculation will typically require between 50 and 100 outer loop iterations to achieve convergence. If you expect that the actual flow being simulated would take a long time to reach a steady-state condition, given the initial conditions you have specified, then a greater number of outer loop iterations may be required. In this case, you can usually reduce the number of iterations required by setting initial conditions that more closely resemble the steady state flow. Although a relatively large time scale can be used, if the time scale is too large the resulting convergence behaviour will be “bouncy.” If this is observed, then the first thing you should try is to reduce the time scale, say, by a factor of four. If there is no noticeable improvement, then the convergence problem may be caused by another factor. If the time scale is too small, then the convergence will be very slow.

In addition to the advice in the following sections, you will probably require a small physical time scale for the following situations:

1-Poor mesh quality.

2-Transonic flow

3-Large regions of separated flow

4-Opening with simultaneous inflow and outflow

5-Free Surface flows: In these cases it is often sufficient to use a smaller timestep only for the Volume Fraction equations

6-Multiphase flows

A steady-state calculation will typically require between 50 and 100 outer loop iterations to achieve convergence. If you expect that the actual flow being simulated would take a long time to reach a steady-state condition, given the initial conditions you have specified, then a greater number of outer loop iterations may be required. In this case, you can usually reduce the number of iterations required by setting initial conditions that more closely resemble the steady state flow. Although a relatively large time scale can be used, if the time scale is too large the resulting convergence behaviour will be “bouncy.” If this is observed, then the first thing you should try is to reduce the time scale, say, by a factor of four. If there is no noticeable improvement, then the convergence problem may be caused by another factor. If the time scale is too small, then the convergence will be very slow.

In addition to the advice in the following sections, you will probably require a small physical time scale for the following situations:

1-Poor mesh quality.

2-Transonic flow

3-Large regions of separated flow

4-Opening with simultaneous inflow and outflow

5-Free Surface flows: In these cases it is often sufficient to use a smaller timestep only for the Volume Fraction equations

6-Multiphase flows

Maximum Number of Iterations

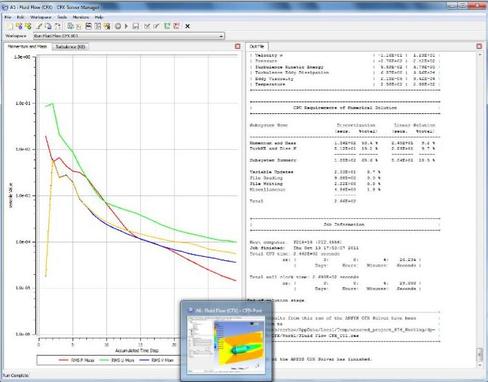

Once you verify you can run a steady state case, you need to see how the solution is converging, if there are no irregularities and the iteration curves are smooth that means your mesh is capturing the flow properties. The first 5 to 10 iterations you will see that the solution is not smooth but as the iteration process progresses the curves start getting smother for velocities and pressure. Usually for a channel flow case what you will see if the flow is in the x axis direction that the u velocity component will fluctuate more through the iteration process and that is natural because the flow energy is in the x axis direction is the highest, while you will see that v and w component are nearly very similar. Usually the pressure iteration curve is a bit different from the three u,v and w iteration curves, you need to check that pressure curve smoothness that it stays steady through the iteration process, this will prove to you that either the coarse mesh you have selected is ok or you will have to yes medium or fine mesh in order for those pressure fluctuation in not to occur.

Regarding the number of maximum iterations, the number of iterations is just to get the best converged solution, as an example sometimes you will see the first 10 iterations are not smooth but once it gets to 20 iterations the convergence will just stay fixed with no change, this means there is no reason for you to chose more than 20 iterations because that would only increase your calculation time for the simulation in addition to that you won’t gain anything from that action you will only be delayed to reach your work dead line.

Just to note that parts of this section base material has been taken from the CFX online material (http://www.sharcnet.ca/Software/Fluent13/help/cfx_mod/i1313401.html#solv_file_ed) and is graudually being re-written in a more basic manner for the researcher to understand.

Unless otherwise noted, all content on this site is @Copyright by Ahmed Al Makky 2012-2014 - http://cfd2012.com